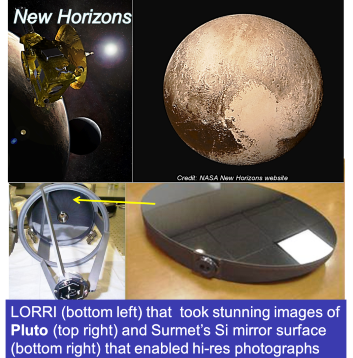

Surmet contributed the critically enabling mirror-surface technology for the New Horizons mission.

Technology and Solutions:

Surmet's foundation was based on expertise in Surface Metallurgy as the name SURMET may indicate. It's coating technologies are based on High Vacuum Technology. Surmet has a proven track record of providing many enabling technologies over the years including Amorphous Si coating that provided the critical mirror surface required for taking hi-res images by the LORRI telescope for NASA's New Horizons mission.

Surmet's focus has been solving customers' problems and provide cost-effective, advanced materials based solutions that result in lasting value. Surmet has had many unique and significant accomplishments over the years, serving the Advanced Materials and Surface Metallurgy needs of next generation applications in Global Semiconductor Equipment, Biomedical, Aerospace and Defense and other industries. Electrostatic clamp that has been a standard in the fab lines across the globe, UHP Silicon coating for semiconductor chambers and mirrors for telescopes, UltraC diamond-like-carbon (DLC) for wear applications in aerospace industry, etc. are a few examples.

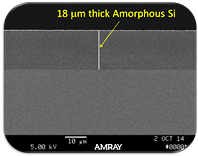

Ultra high purity, atomically homogenous Amorphous Silicon coating

Unique and proprietary Silicon coating technology that was developed and perfected in early 2000s by Dr. Suri Sastri, the Foun der, CEO and President of Surmet Corp. has outstanding features/characteristics. It is strongly adherent, amorphous and supremely homogeneous (at an atomic scale), the coating applied to the mirror substrate of the telescope allows for single point diamond turning and finish polishing, meeting the most stringent wavefront specifications required for capturing ultrahigh resolution images from outer space. Dr. Sastri's unique innovation allows this coating to be deposited in thicknesses of up to 250 microns. der, CEO and President of Surmet Corp. has outstanding features/characteristics. It is strongly adherent, amorphous and supremely homogeneous (at an atomic scale), the coating applied to the mirror substrate of the telescope allows for single point diamond turning and finish polishing, meeting the most stringent wavefront specifications required for capturing ultrahigh resolution images from outer space. Dr. Sastri's unique innovation allows this coating to be deposited in thicknesses of up to 250 microns.

|

|

Recommended Publications:

|

|

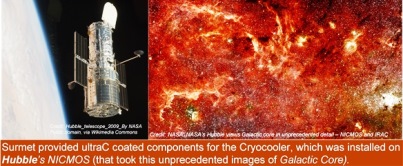

UltraC Diamond-like Carbon (DLC) on the Hubble mission

New Horizons isn't the first mission that Surmet ventured into. Back in 2003, Surmet provided another enabling technology for a critical component of the Cryocooler that was part of Hubble Telescope's infrared imaging system NICMOS. Surmet's ultraC diamond-like carbon (DLC) provided the wear resistance that was needed for this component to spin at RPMs of >6000.

Surmet's Current Focus

With expertise in variety of coatings and surface engineering solutions, Surmet

is now focussing on solving customers' materials related problems. Examples of solutions include specialty coatings for wear and chemical resistance, ultra-low coefficient of friction, electrical properties, optical properties, mirror applications, etc. for the aerospace, defense and other industries.

|